My Yugo Mauser has that problem. The feed ramp has a sharp edge on it and shaves off the brass. Since it mostly sits in the safe, I've never bothered to file it down smooth as it only gets maybe 10 rounds a year through it.

Yowza! Had the wife open the package w the DelTon and use her magical index finger to “gauge” the Combat Armory feed ramps compared to the DelTon.

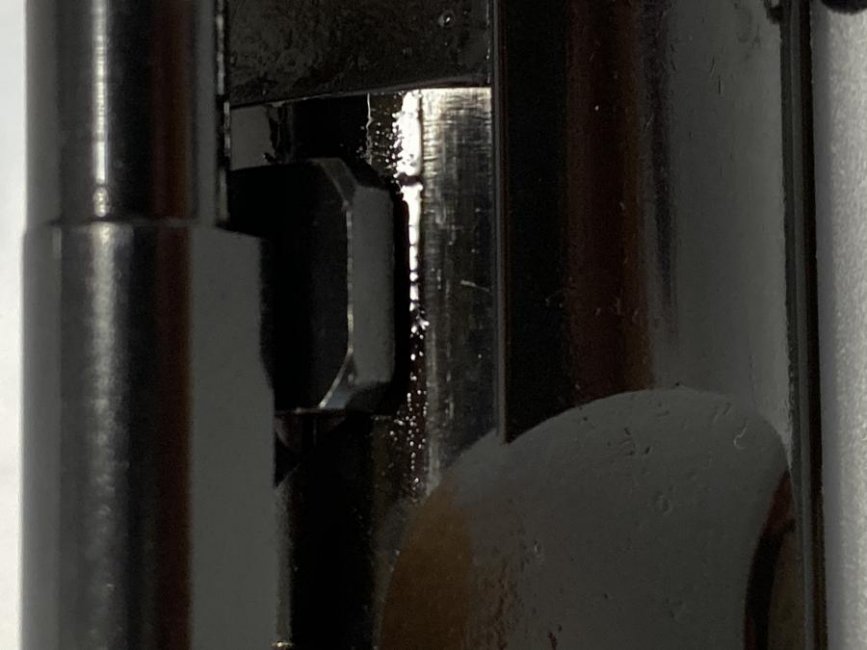

She said if ive fired 40 rds through the CA the fed ramps probably would’ve cut her fingertips before, they are so sharp compared to the DelTon ….!

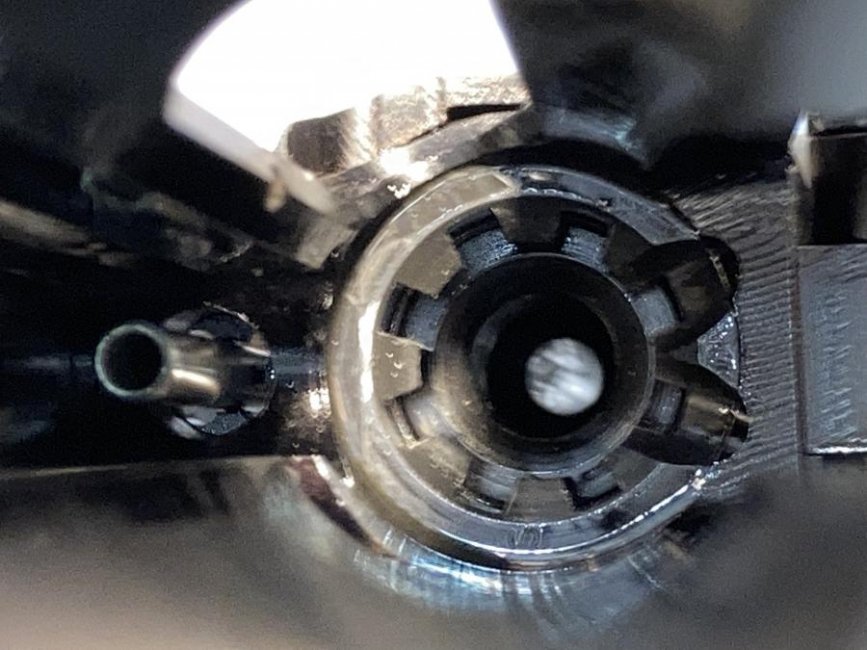

First pic is DelTon, following pics Combat Armory

I bought a Pyramid trigger from Glockstore and had the same problem when I built my Poly80 G17. Tested the slide with a stock G22 to make sure it wasn't a slide issue, and ended up trashing the trigger for OEM (About $180 gone because it was outside of return window due to COVID parts delays). Overall it seems that aftermarket triggers may have tighter tolerances than stock which may cause issues with the trigger connector lowering enough to release the striker. Of course, that was with a Poly80 build and not an OEM Glock...If you've got the OEM Trigger, I'd toss that in to see if it works like that or not.

Goose bumps. Yep. I tried the oem trigger assembly last night before calling it quits at 3am and functions normally. Gonna reach out to Lone Wolf.