GunBum

Active Member

I picked up this Gras action for a song several years ago. It was missing the extractor. Unfortunately, Gras extractors are unobtanium in the US, but are quite plentiful in France. Who would have thought?  Anyway, I have a friend in Germany who has a girlfriend that speaks French and was able to order me an extractor off the internet. The extractors are quite fragile. I hope it doesn’t break because I have more money in the extractor than the rest of the action.

Anyway, I have a friend in Germany who has a girlfriend that speaks French and was able to order me an extractor off the internet. The extractors are quite fragile. I hope it doesn’t break because I have more money in the extractor than the rest of the action.

Anyway, I have a friend in Germany who has a girlfriend that speaks French and was able to order me an extractor off the internet. The extractors are quite fragile. I hope it doesn’t break because I have more money in the extractor than the rest of the action.

Anyway, I have a friend in Germany who has a girlfriend that speaks French and was able to order me an extractor off the internet. The extractors are quite fragile. I hope it doesn’t break because I have more money in the extractor than the rest of the action.

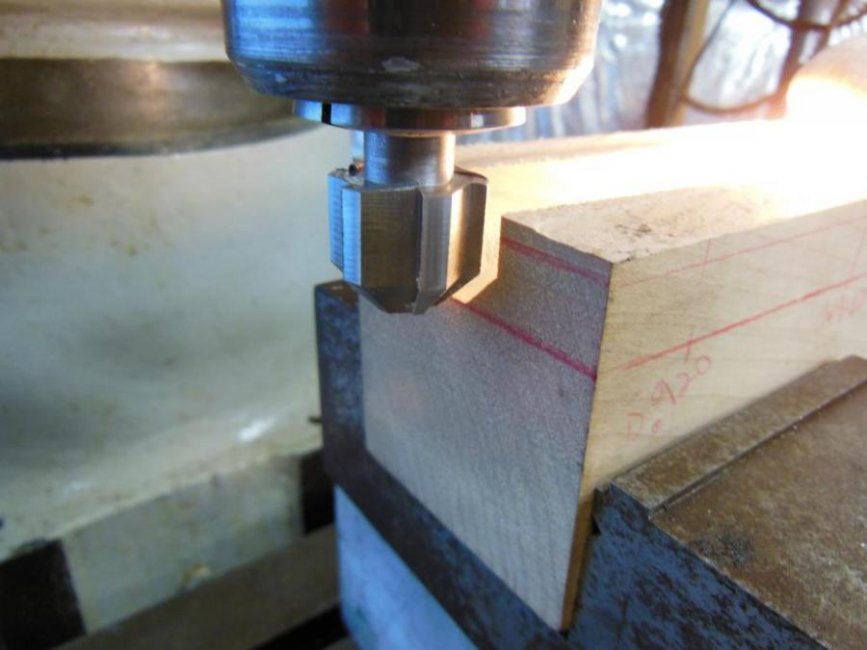

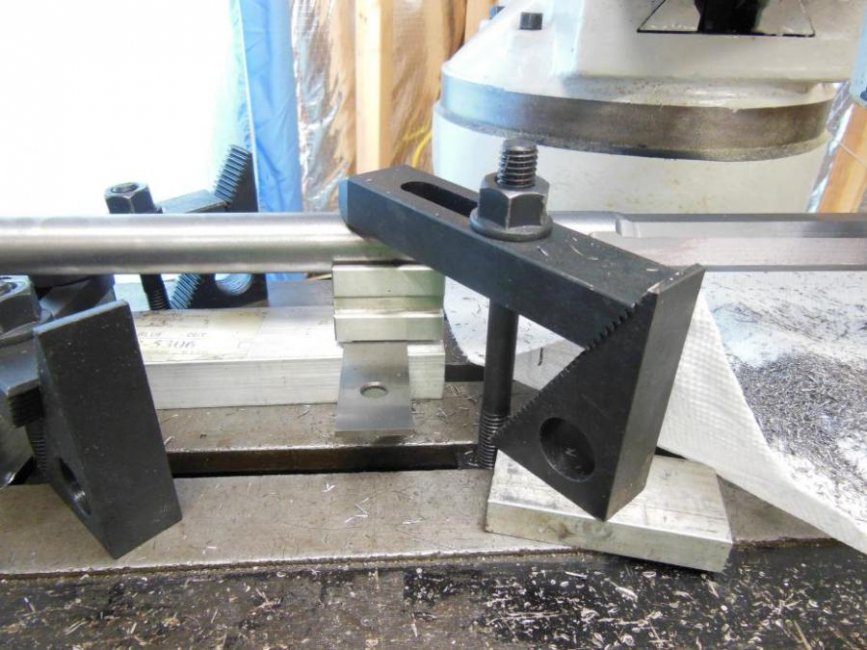

So I sat, and watched the mill table move 14” (that’s about 7 minutes per pass), rotated the spindexer, and cut again... and again... and again...

So I sat, and watched the mill table move 14” (that’s about 7 minutes per pass), rotated the spindexer, and cut again... and again... and again...

)

)