shocker998md

Ultimate Member

Hey guys,

Id like to get some opinions on a rifle I picked up to help me a direction to go in. Ice always been a tinker type of guy, I reload because of the mechanical side to it. I build engines, cars, bikes, and am alawys messing with stuff.

I scored an older rem 700 270 a few weeks ago. I cleaned it and got all all the fouling out, poped it out of the stock and noticed two things.

1. There aren't any inserts, washers, or anything for the holes in the stock for the two action screws. This just screams to me that when I tighten up the stock its never consistant.

2. Is it has a pressure point at the front sling swivel, so the barrel isnt floated.

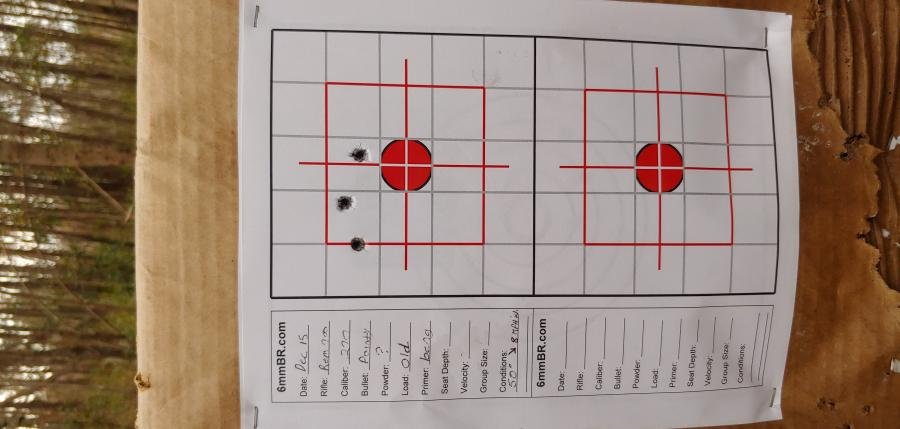

Right now ive shot one type of roubd through it. It shot about a 1.5 inch group, ran about 2650 fps with a deviation in the 40 fps range. So ive got tons of ammo work to do.

In what order of things should I mess with it? I'm thinking 1. Then dial in ammo and if its good enough its done. The trigger is nice, I just was to dial it in better since theres some not expensive things that can improve consistency

Id like to get some opinions on a rifle I picked up to help me a direction to go in. Ice always been a tinker type of guy, I reload because of the mechanical side to it. I build engines, cars, bikes, and am alawys messing with stuff.

I scored an older rem 700 270 a few weeks ago. I cleaned it and got all all the fouling out, poped it out of the stock and noticed two things.

1. There aren't any inserts, washers, or anything for the holes in the stock for the two action screws. This just screams to me that when I tighten up the stock its never consistant.

2. Is it has a pressure point at the front sling swivel, so the barrel isnt floated.

Right now ive shot one type of roubd through it. It shot about a 1.5 inch group, ran about 2650 fps with a deviation in the 40 fps range. So ive got tons of ammo work to do.

In what order of things should I mess with it? I'm thinking 1. Then dial in ammo and if its good enough its done. The trigger is nice, I just was to dial it in better since theres some not expensive things that can improve consistency