If you really want to maximize things and go TOTAL OCD, you want to vary powder charges and seating depth AND crimp pressure. Oh and case manufacturer and primer. It's okay, you might only have about 20,000 combinations to maximize your load.

Yes, I am being very tongue in cheek. The recommendation to work on powder charge and then seating depth is the way to go. That said, depends on exactly what you are trying to achieve. Just finding your accuracy node for powder charge might just get you the accuracy you want. Tweaking seating depth and other components (other than maybe bullet selection from a generic FMJ to a match bullet) might take you from a 1MOA load to a .7MOA load or whatever. Might be what you want to chase. Might not be. Just depends on you. For me I don't have time to do that. Eventually I probably will. Especially once components are easier to source.

For me I am personally just chasing a safe, reasonably accurate load with the components I have. See what I get for accuracy and if it is good enough it is good enough. I haven't worked up .308 or .30-06 loads yet, but for >10gr loads I work it up .5gr at a time from starting to max. For <10gr I load .2gr at a time from starting to max. Especially since most loads aren't a nice even .5gr what I'll do is something like my .30 carbine loads, max was 14.7gr H110 (IIRC), so I started at 13gr, then 13.5, 14, 14.5 and then 14.7gr. Smaller jump to get to max so I am testing a load just slightly less than max first to make sure that looks good.

If I need better accuracy/consistency than what I saw, I'll go back and test with finer increments later. Like my CFE223 load for .223. I hadn't tested to max the first time out, but 25gr was a lot better than others, so I'll probably load 25gr, 25.2gr, 25.4gr, 25.6gr. Especially since a lot of what I've read is CFE223 really likes near max loads.

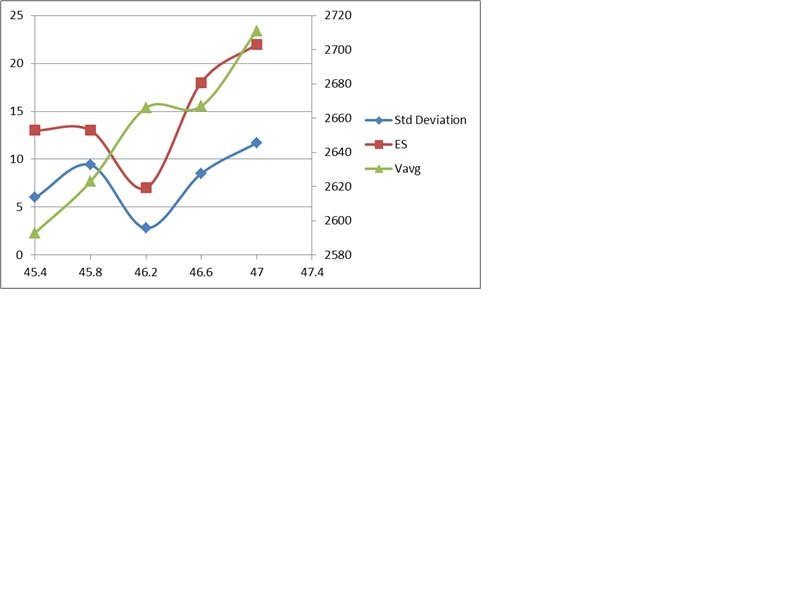

Pistol I am pretty much all shooting off hand for testing and for all my shooting unless I am trying to do something like snipe bowling pins at 50yds or something. So I don't really look at accuracy, unless something seems off. I just look at SD, ES and how sooty the cases are to figure out where I want my loads.

Yes, I am being very tongue in cheek. The recommendation to work on powder charge and then seating depth is the way to go. That said, depends on exactly what you are trying to achieve. Just finding your accuracy node for powder charge might just get you the accuracy you want. Tweaking seating depth and other components (other than maybe bullet selection from a generic FMJ to a match bullet) might take you from a 1MOA load to a .7MOA load or whatever. Might be what you want to chase. Might not be. Just depends on you. For me I don't have time to do that. Eventually I probably will. Especially once components are easier to source.

For me I am personally just chasing a safe, reasonably accurate load with the components I have. See what I get for accuracy and if it is good enough it is good enough. I haven't worked up .308 or .30-06 loads yet, but for >10gr loads I work it up .5gr at a time from starting to max. For <10gr I load .2gr at a time from starting to max. Especially since most loads aren't a nice even .5gr what I'll do is something like my .30 carbine loads, max was 14.7gr H110 (IIRC), so I started at 13gr, then 13.5, 14, 14.5 and then 14.7gr. Smaller jump to get to max so I am testing a load just slightly less than max first to make sure that looks good.

If I need better accuracy/consistency than what I saw, I'll go back and test with finer increments later. Like my CFE223 load for .223. I hadn't tested to max the first time out, but 25gr was a lot better than others, so I'll probably load 25gr, 25.2gr, 25.4gr, 25.6gr. Especially since a lot of what I've read is CFE223 really likes near max loads.

Pistol I am pretty much all shooting off hand for testing and for all my shooting unless I am trying to do something like snipe bowling pins at 50yds or something. So I don't really look at accuracy, unless something seems off. I just look at SD, ES and how sooty the cases are to figure out where I want my loads.