I’ve adjusted the Lee powder expander so that the case is flared just so that the projectile will

Fit in the casing. After seating the bullet and before crimping, the bullet won’t fully seat into my case gauge. The bullets will fit into the chamber of both firearms.

Looking for leads to follow to resolve this issue.

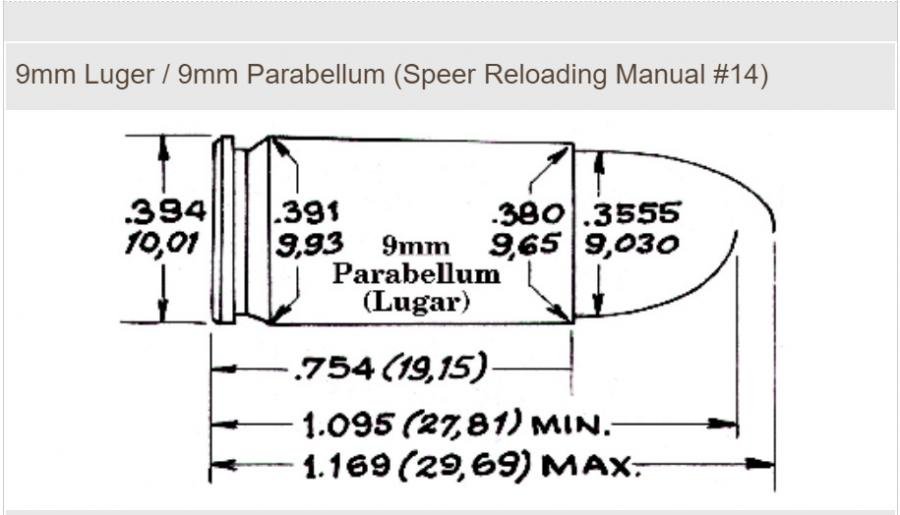

That is correct. The crimping die will straighten out bell that was put in the case. I adjust my factory crimp die for a diameter of .379. After closing the bell with the seat die or a crimp die, it should fit your case gauge.