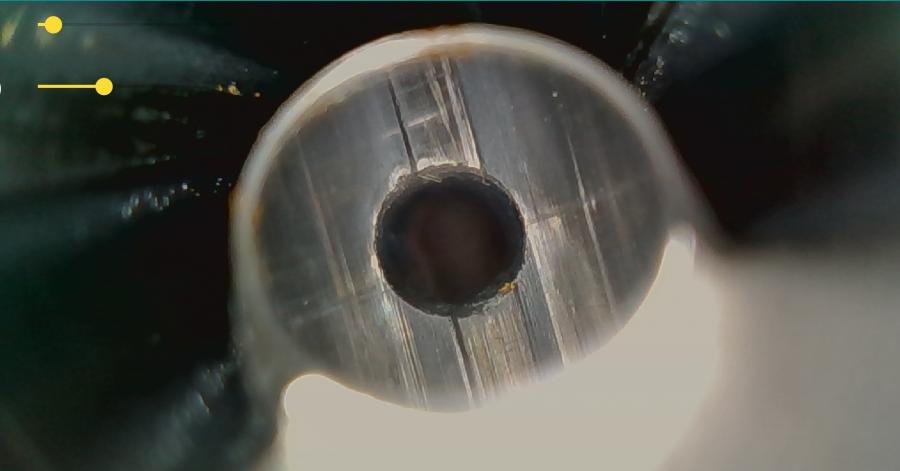

Bore scope

Magpul BEV block

Long Allen wrench set for SAE and Metric

Inspection picks

Magpul Armorer wrench

Small needle nose pliers

Utility knife w/razor blade

Torque wrench 1/2"

Breaker bar 1/2"

Aeroshell 64

Loctite 720

Tack hammer (get one at Lowe's)

Screwdrivers (flat and Phillips)

Torx wrench set

Sotaracha

Lapping tool

Lapping compound

Mobil 1 Synthetic oil

Wheeler AR15/AR10 vice block (used when lapping the upper)

Feeler gauges

Punch set

Roll pin punch set

Roll pin starter punches

223 GO, 556 GO, 556 FIELD headspace gauges (pacific tool and gauge will also modify them for a small fee, so they will clear the extractor and ejector)

Cordless drill (used for lapping the upper)

And many more

I know it’s a typo but it should be Loctite 620 not 720.

Sent from my iPhone using Tapatalk