Magnumite

Ultimate Member

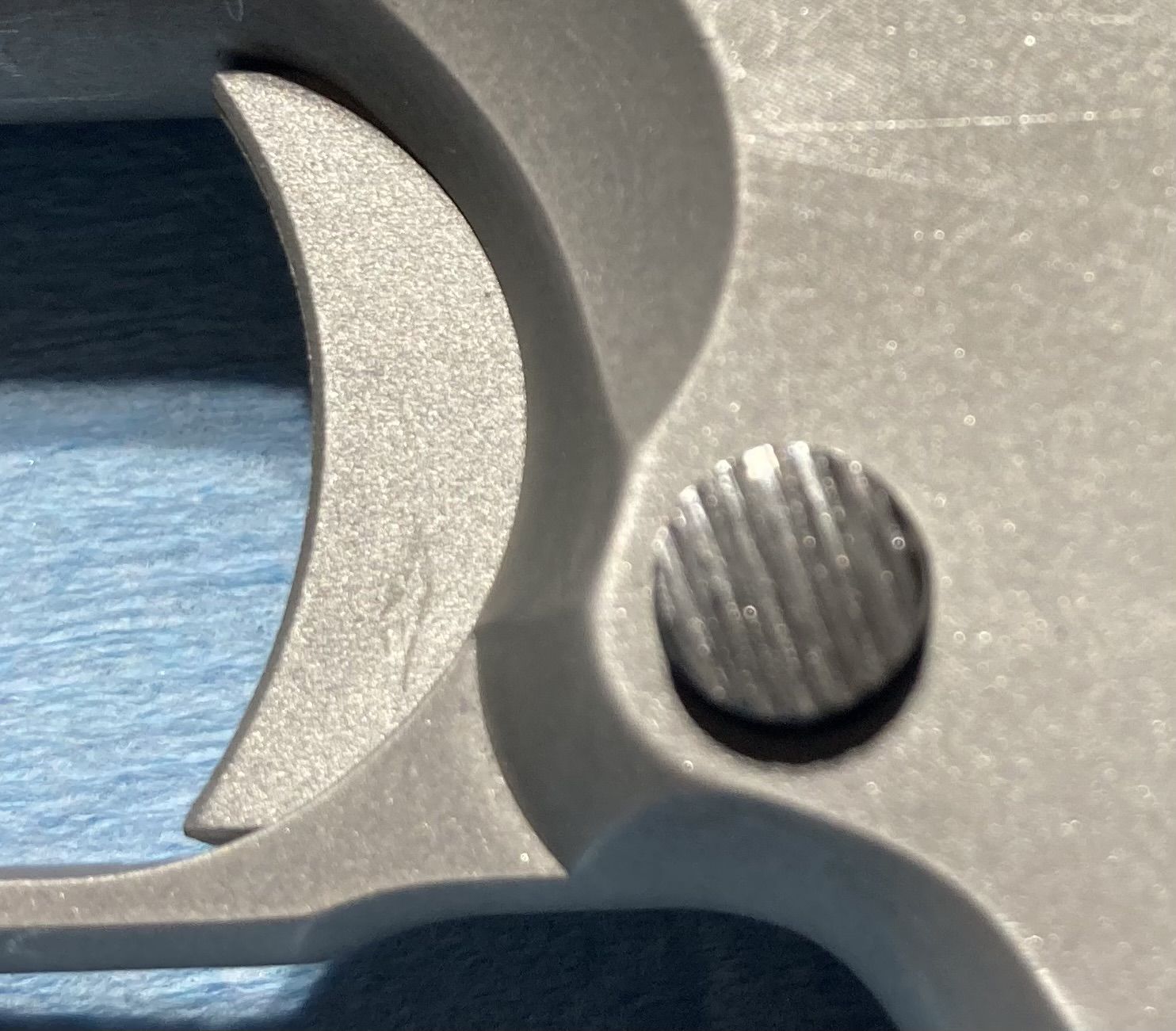

Econo-build in progress, all focused toward carry and defense. Aluminum frame (80% serialized), bobtail mainspring housing, concealment hammer and grip safety. Info and parts used as follows.

So…about a 65% aluminum frame. Vision:

- carry/defensive setup;

- concealed carry machined cc grip safety;

- concealment hammer, accompanying sear, and disconnector;

- bobtail housing…had to try it;

- actually hoping it would rival my LW CCO builds.

Some notes.

1.). The aluminum used was a good alloy, much harder than I expected.

2.) deck, rails, barrel bed, hammer sear pin holes, feed ramp, grip screw bushing holes need(-ed) machining.

3.) The bore at the barrel lug cut out was machined too small. Soooo….the rear centering diameter of the recoil spring guide had to be fitted;

4.) The frame deck was uneven on its surface and varied .002” from side to side.

Onto the pistol. 45 ACP full size pistol bobtail pistol. Specifics of parts used….

Takeoffs include the mag catch, firing pin, thumb safety, barrel, and recoil guide rod and plug.. All other parts are new.

————-

Why the bobtail? I never had much of an itch for a 1911 so equipped. After shooting my CCO’s with round butts…well it got me to thinking. An aluminum full size frame…it made sense.

So…about a 65% aluminum frame. Vision:

- carry/defensive setup;

- concealed carry machined cc grip safety;

- concealment hammer, accompanying sear, and disconnector;

- bobtail housing…had to try it;

- actually hoping it would rival my LW CCO builds.

Some notes.

1.). The aluminum used was a good alloy, much harder than I expected.

2.) deck, rails, barrel bed, hammer sear pin holes, feed ramp, grip screw bushing holes need(-ed) machining.

3.) The bore at the barrel lug cut out was machined too small. Soooo….the rear centering diameter of the recoil spring guide had to be fitted;

4.) The frame deck was uneven on its surface and varied .002” from side to side.

Onto the pistol. 45 ACP full size pistol bobtail pistol. Specifics of parts used….

- WC concealment hammer, disco, sear;

- Remington R1 trigger;

- Ed Brown machined concealment beavertail;

- Tisas slide, new…one of the ones on sale;

- Colt Mk IV barrel bought from a member several years ago;

- EGW, IIRC, carry bevel stainless bushing;

- Ed Brown chain link carbon machined mainspring housing;

- takeoff Safariland ambi safety. This has been one of the most enduring tongue and groove retention thumb safeties I used. It was removed from one of my pistols I converted to single side safety

- EGW practical extractor;

- EGW ejector;

- TMC machined plunger tube;

- Ed Brown rebuild pin kit;

- TWC firing pin stop;

- Ruger, I think so anyway, takeoff titanium firing pin;

- a couple mim parts for gasps and giggles…this pistol isn’t going anywhere. S&W slide stop, mag catch, and thumb safety.

Takeoffs include the mag catch, firing pin, thumb safety, barrel, and recoil guide rod and plug.. All other parts are new.

————-

Why the bobtail? I never had much of an itch for a 1911 so equipped. After shooting my CCO’s with round butts…well it got me to thinking. An aluminum full size frame…it made sense.

Last edited: