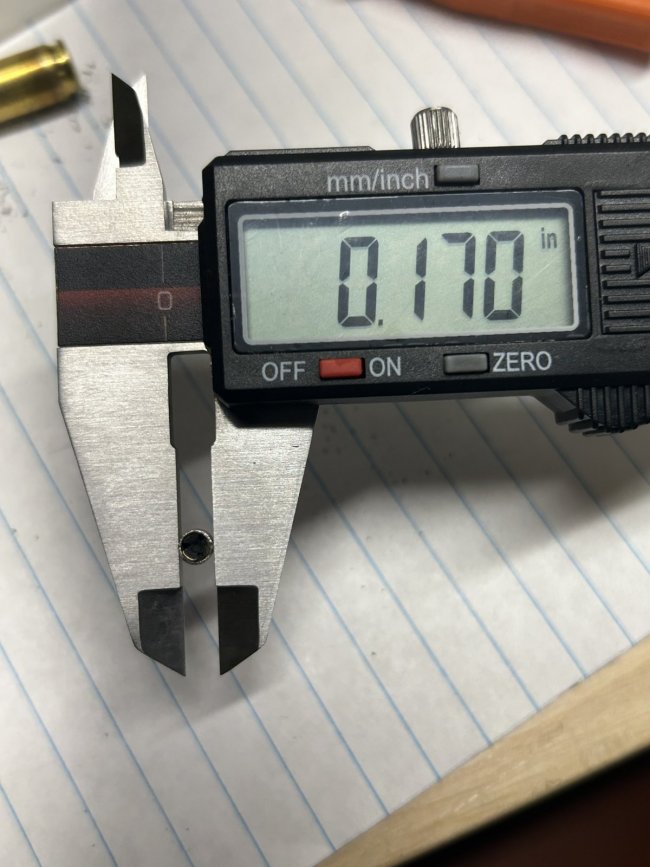

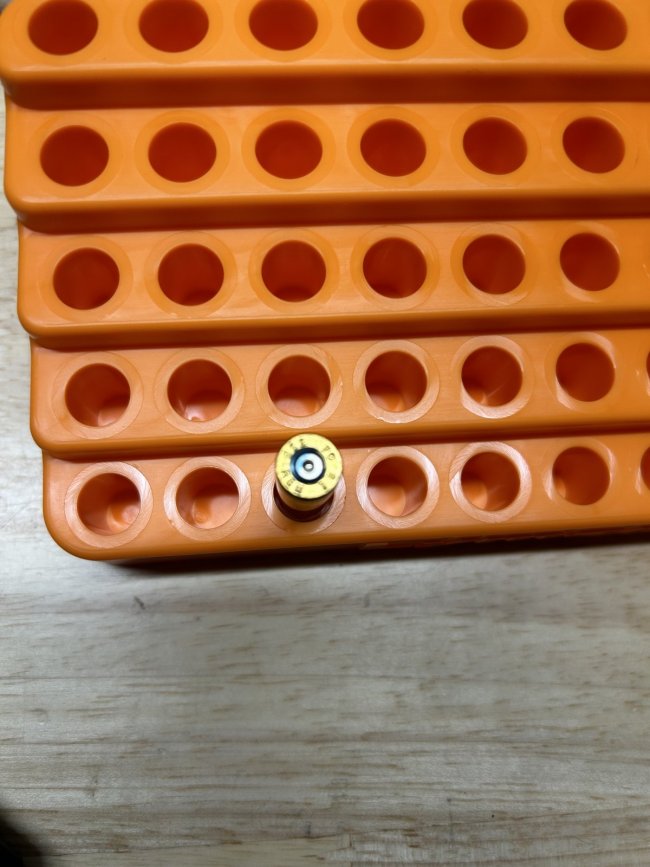

Want to reload 223 cases. Spent primer measures .170, appears to be surrounded by metal ring in the primer pocket to fit. Regular.175 primer does not fit. What’s going on? Don’t know if ring is removable. Pictures attached. Thanks in advance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sierra MatchKing Competition Ammunition 223 - primer pocket size atypical- has ring inside pocket?

- Thread starter Clay

- Start date

The #1 community for Gun Owners of the Northeast

Member Benefits:

No ad networks! Discuss all aspects of firearm ownership Discuss anti-gun legislation Buy, sell, and trade in the classified section Chat with Local gun shops, ranges, trainers & other businesses Discover free outdoor shooting areas View up to date on firearm-related events Share photos & video with other members ...and so much more!

Member Benefits:

whistlersmother

Peace through strength

Look like primer pocket crimps.

If so, you'll need a tool to ream out the crimp.

If so, you'll need a tool to ream out the crimp.

- Jul 29, 2014

- 50,073

Yup. Military crimp. If you don't have a swaging tool, you can use a chamfer tool(the inside end) and grind it off manually. It's slow, but it works if that's your only option.Look like primer pocket crimps.

If so, you'll need a tool to ream out the crimp.

About 4 turns of the chamfer tool will take enough off so that the primer will go in.Yup. Military crimp. If you don't have a swaging tool, you can use a chamfer tool(the inside end) and grind it off manually. It's slow, but it works if that's your only option.

I like mine, but it's a bit of a bear for mixed brass. On-press swage tended to be a little easier to use.

I quite swaging.

My buddy showed me a slick trick. Put a .50bmg chamfer tool in a 5c collet in the milling machine, grab a handful of cases, just barely touch each pocket to the tool at about 400 to 500 rpm. Haven't had a deformed case head or bent rim since.

My buddy showed me a slick trick. Put a .50bmg chamfer tool in a 5c collet in the milling machine, grab a handful of cases, just barely touch each pocket to the tool at about 400 to 500 rpm. Haven't had a deformed case head or bent rim since.

Lol. Good point. With reloading it really is a question of how much to invest in time and tools v buying a product. Wouldn’t surprise me if there are people who machine their own brass from stock (I’m going to Google this now)Get some new brass.

They do but not for the type of cases you are probably thinking about.Lol. Good point. With reloading it really is a question of how much to invest in time and tools v buying a product. Wouldn’t surprise me if there are people who machine their own brass from stock (I’m going to Google this now)

Know one guy who turned his own 8 bore cases to match the Holland double he bought.

Another makes them for his 37mm Hotchkiss mountain gun.

Huh. Thanks!!!I quite swaging.

My buddy showed me a slick trick. Put a .50bmg chamfer tool in a 5c collet in the milling machine, grab a handful of cases, just barely touch each pocket to the tool at about 400 to 500 rpm. Haven't had a deformed case head or bent rim since.

Well, he does happen to have all the shit to load 50bmg and 20mm, plus a milling machine with collets so, why not.Huh. Thanks!!!

It's probably not the safest thing but he and I are used to working around machine tools and it works really well. The Dillon super swage sits in a box somewhere unused.

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

Forum statistics

Latest threads

-

-

-

-

Grand Power Stribog Restocked 9mm & 10mm $689.95 to $1649.00 Shipped

- Started by DK Firearms

- Replies: 0

-

-

-